Our industry—leading innovations harness the power of chemistry to bring everyday convenience to virtually everything people touch.

The History of Chemours

A different kind of chemistry company with 200 years experience

Our History

Two-hundred years of innovation and counting

Our Journey: From Transformation

July 2021

Chemours’ Founding CEO Retires

Mark Vergnano served as President and Chief Executive Officer from the company's inception—in July 2015—through June 2021.February 2021

Fluoroproducts Business Separates

Chemours divided its Fluoroproducts business into two new business segments: Thermal & Specialized Solutions (TSS) and Advanced Performance Materials (APM). This change enables our customer-centered approach and continued innovation.March 2020

The Chemours Discovery Hub Officially Opens

Through its new innovation center, Chemours brought all of its U.S. researchers under one roof intending to foster innovation and collaboration.October 2018

Launch Corporate Responsibility Commitment

We're dedicated to responsible chemistry—so much so that we're building it into the way we do business and the way we grow, balancing the essential with the responsible.January 2018

A New Chapter of Growth

We are earning our way to growth by advancing innovative chemistry and through our four growth pillars of Portfolio, Partnerships, Performance, and People.December 2017

Our Inaugural Investor Day

We mark the completion of our five-point transformation plan and announce 5x increase in quarterly dividend and $500 million Share Repurchase Plan.December 2017

Investing in the Future of Discovery and Innovation

We break ground on a $150 million state-of-the-art innovation center at University of Delaware’s Science, Technology, and Advanced Research Campus.June 2017

Fortune 500

In less than two years, we make the 2017 Fortune 500 list.February 2017

Beating the Street

We settle our indemnification obligations, mitigating risk and uncertainty. Our stock breaks $30 per share.January 2017

Our New Home

Our global HQ in the historic DuPont building becomes our permanent location.November 2016

Delivering on Our Promises

Adjusted EBITDA improves; strong earnings and margin increases. Stock breaks $20 per share.August 2016

Making Steady Progress

Sale of three businesses and pay down of $150 million debt.January 2016

Facing Challenges

As pressure builds, our stock falls below $4 per share.November 2015

Investing in the Future

We launch the world’s first full-scale production facility for Opteon™ low GWP products.August 2015

Our Five-Point Transformation Plan

Start of transformation to reach our full potential for customers, investors, employees, and society.July 2015

Our New Company

Officially an independent company.Titanium Technologies

2017

We Are Now a Fortune 500 Company

In fewer than two years, Chemours has become an enterprise finding its footing and realizing its potential among the global commercial elite. The company’s success is built on strong values, which include an unwavering focus on customers. And the five-point transformation plan keeps all 7,000+ employees applying the same formula for success throughout the journey. 2016

Our Home Is in Wilmington

The global headquarters of Chemours Titanium Technologies remains in Wilmington, Delaware. Staying in this fiscally responsible locale will help stimulate future growth and attract great talent. 2016

Altamira Expands

An investment of over $600 million at the Ti-Pure™ plant in Altamira, Mexico, significantly increases capacity starting in 2016. The plant serves global customers and help keep Chemours the world's largest TiO2 producer. 2014

Ti-Pure™ One Coat

The Ti-Pure™ One Coat system is introduced. It combines market insight, formulation expertise, and innovative products such as Ti-Pure™ TS-6300 to expand the limits of hiding power. 2013

Changing the Formula

The spin-off of the titanium dioxide businesses within DuPont Performance Chemicals is announced, launching the Chemours Titanium Technologies business. 2010

Brighter Homes

Floors, cabinets, and furniture gain lasting brightness with Ti-Pure™ R -796+, formulated to support the world's rising demand for diverse laminates for homes, offices, and public spaces. 2006

Energy Efficiency

Ti-Pure™ R-902+ helps customers shrink energy costs. A new formulation lets manufacturers use as much as 50% less energy to disperse pigment evenly in paint. 2005

Performance Plus

As use of polyolefins expands, so do performance demands. Ti-Pure™ R-350 is designed to support thinner films and faster production speeds in a range of new applications, such as packaging, flexible foam, and pharmaceuticals. 2002

The Nature Conservancy

Six hundred acres of timberland owned by the Ti-Pure™ plant in DeLisle, Mississippi, is donated to the Nature Conservancy, which turns it over to Mississippi as part of the state’s Coastal Preserves Program. 2002

The Nature Conservancy

Ti-Pure™ TS-6200 combines high gloss with high durability. The new pigment is formulated to meet the unique functional and aesthetic challenges of automotive, aerospace, and marine coatings. 2000

Sun Protection for Plastics

Manufacturers of plastics used for roofing, fencing, and other outdoor applications gain an extended-life option as a new formulation, Ti-Pure™ R-105, comes to market. 1994

Expanding in Asia

The Kuan Yin, Taiwan, plant opens enabling the Ti-Pure™ business moves to meet growing Asian demand for everything from colorful paints for homes to UV-resistant plastics for construction materials. 1994

Setting a New Standard

Ti-Pure™ R-706 helps coatings manufacturers set new quality and durability standards, with exceptional paint performance across a wide range of interior, exterior, and industrial applications. 1993

Adding Shelf Appeal

As demand for innovative packaging designed to drive shelf appeal takes shape, Ti-Pure™ R-104 for brighter whites and easier processing in plastics helps customers keep up. 1990

Exporting Expertise

To meet increasing global demand for specialized applications, a new technical center opens at our Mechelen, Belgium, site. 1979

Preserving Habitat

Ti-Pure™ production expands to keep pace with growing demand opening a new plant in DeLisle, Mississippi. Of the site’s approximately 4,000 acres, about 1,000 are maintained as wildlife habitat. 1976

100% Chloride Chemistry

The final Ti-Pure™ production plant still using the older sulfate method converts to the chloride process, completing our adoption of the most advanced processing technology then – and now. 1973

Expanding in Europe

The Antwerp, Belgium, distribution center opens to serve the increasingly large global market for Ti-Pure™ pigments. 1965

Increasing Durability

The chemistry of Ti-Pure™ evolves. A new formulation, Ti-Pure™ R-960, raises durability to new levels for automotive, aerospace, and industrial equipment exterior finishes. 1959

First Non-US Plant

As business becomes increasingly global, Titanium Technologies opens its first facility outside US borders. The Altamira, Mexico, plant upgrades both supply and support for customers in Mexico, Central, and South America. 1959

Thinking Bigger

The world’s largest TiO2 plant—designed to meet growing demand from at home and abroad—opens. In addition to advanced production capabilities, the design incorporates stewardship, as the New Johnsonville, Tennessee, plant sits on a 1,500-acre wildlife preserve. 1949

Lower-Impact Mining

A new mineral-mining operation opens in Starke, Florida. It uses meticulous planning and processes to extract valuable blasting minerals while maintaining wetlands, forests, and wildlife habitat—an approach that continues today. 1948

Chloride Technology

A change in chemistry revolutionizes TiO2 production. New chloride technology developed by our team at the Edgemoor, Delaware, Ti-Pure™ facility enables more efficient production of high-quality titanium dioxide. Today, it is the production technology used across all of Titanium Technologies. 1941

A New Source of White

New processing technology makes it possible to bring high-quality pigments made from rutile titanium ores to market. Previously, it had been too expensive to produce pigments from these ores, despite the high-quality TiO2 they contain. 1935

Transforming Production

As chemistry decreases the cost of titanium dioxide production down and raises its quality, our first dedicated Ti-Pure™ plant opens in Edgemoor, Delaware, a site that previously housed an iron mill which produced girders for the Brooklyn Bridge. 1931

Ti-Pure™: A New Standard

With the purchase of the Commercial Pigments Corporation, DuPont enters the TiO₂ business. Ti-Pure™ pigments immediately offer the superior brightness of TiO₂. While improvements over the years transform products and processes, the Ti-Pure™ brand remains the heart of the Titanium Technologies business. 1917

First Pigments Business

Lithopone—a white pigment composed of a mixture of barium sulfate and zinc sulfide—marks DuPont's first foray into making pigments. While TiO₂ soon displaces lithopone, the business knowledge gained provides a foundation for the launch of Ti-Pure™.Thermal & Specialized Solutions

2017

We Are Now a Fortune 500 Company

In less than two years, Chemours has become an enterprise finding its footing and realizing its potential among the global commercial elite. The company’s success is built on strong values, which include an unwavering focus on customers. And the five-point transformation plan keeps all 7,000+ employees applying the same formula for success throughout the journey. 2016

Our Home Is in Wilmington

The global headquarters of Chemours Titanium Technologies remains in Wilmington, Delaware. Staying in this fiscally responsible locale will help stimulate future growth and attract great talent. 2015 - 2016

Growth Across Key Businesses

A rise in customer demand for sustainable automotive refrigerant solutions to meet regulatory changes doubles the global supply of Opteon™ YF. Additionally, we commit to investing in the expansion of the Corpus Christi manufacturing site to triple global capacity for Opteon™. 2014

Opteon™ 1100

The same low global warming potential (GWP) hydrofluoroolefin (HFO) chemistry behind Opteon™ continues to evolve, enabling a new expansion agent for high-performance insulating foams as part of phasing out older hydrochlorofluorocarbon (HCFC) products with larger carbon footprints. 2014

Evolving the Chemistry of Cool

Opteon™ XP40 and XP44 for refrigerators builds on the chemistry of Opteon™ YF for vehicles. By replacing HFC-404A in refrigeration applications, these new HFO products can help meet growing demand for refrigeration with lower global warming potential (GWP). 2013

Changing the Formula

The spin-off of the fluoroproducts businesses within DuPont Performance Chemicals is announced, launching the Chemours Fluoroproducts business. 2011

Low GWP Refrigerants

Breakthrough HFO chemistry leads to Opteon™ YF, a vehicle air conditioning refrigerant with a global warming potential (GWP) of less than 1. That’s a 99.9% reduction relative to the current alternative, R-134a. Over nine million cars use Opteon™ YF by the end of 2015. 2005

Replacing HCFCs

ISCEON™ comes to market as a timely solution that allows cost-effective retrofitting to replace ozone-depleting HCFC refrigerants in existing equipment with non-ozone-depleting HFCs. 1995

Phasing Out CFCs

DuPont produces its last CFCs—ozone-depleting refrigerants and propellants—in developed countries. 1990

Replacing CFCs

Taking a business approach to the problem of ozone depletion, new chemistry powers non-CFC refrigerants with Suva™ and propellants with Dymel™, the start of a new generation of lower-impact fluorochemicals. 1974

Combating Ozone Depletion

As the effects of CFCs used in Freon™ and other refrigerants and propellants become known, DuPont establishes an atmospheric monitoring program to fight ozone depletion, and becomes an early supporter of planning to end the use of CFCs. 1949

Focusing on Fluorochemicals

Ending a decades-long joint venture with General Motors brings full ownership of Freon™ refrigerants to DuPont, reflecting an intensifying focus on developing the full potential of fluorochemicals as the world enters the age of air conditioning. 1930

Freon™: The First Fluoroproduct

Discovered by General Motors scientists, Freon™ (chlorofluorocarbon or CFC) makes possible widespread use of refrigerators and air conditioners and serves as a propellant in aerosol sprays. DuPont is chosen for commercial production of Freon™ marking the beginning of our Fluoroproducts business. 1890

The Swarts Reaction

The work of Belgian chemist Frédéric Swarts during the 1890s yields the first chlorofluorocarbon, CF2CI2 and other similar compounds. His discovery lays the foundation for the creation of Freon™ decades later.Advanced Performance Materials

2017

We Are Now a Fortune 500 Company

In less than two years, Chemours has become an enterprise finding its footing and realizing its potential among the global commercial elite. The company’s success is built on strong values, which include an unwavering focus on customers. And the five-point transformation plan keeps all 7,000+ employees applying the same formula for success throughout the journey. 2016

Our Home Is in Wilmington

The global headquarters of Chemours Fluoroproducts remains in Wilmington, Delaware. Staying in this fiscally responsible locale will help stimulate future growth and attract great talent. 2015

Chemistry for Rainy Days

Chemours develops Teflon EcoElite™, a 60% renewably sourced, non-fluorinated, water-resistant finish that’s up to 3x more durable than competitors. Our customer uses this breakthrough technology to launch the first renewably sourced outerwear line in fall 2016. 2013

Changing the Formula

The spin-off of the fluoroproducts businesses within DuPont Performance Chemicals is announced, launching the Chemours Fluoroproducts business. 2013

Elimination of PFOA

Responding to studies showing low levels of perfluorooctanoic acid (PFOA) in the blood of the general population, DuPont stops making and using PFOA 18 months ahead of its goal. Today, Chemours continues this legacy of stewardship and does not make PFOA or use PFOA in any of its products. 2012

Reducing Downtime

To reduce damage and downtime, a customer requests more heat-resistant cable insulation, leading Dr. Jacob Lahijani to invent ECCtreme™ ECA fluoroplastic, rated for heat tolerance for use up to 300 °C (572 °F), about 40 °C (104 °F) higher than previous options. 2010

Technology Takes Off

As new technologies emerge, chemistry evolves. Teflon™ branded polymers find new and vital applications from semiconductor making to smartphone antennae. Other fluoropolymers support safer military communications and potential power transmission via Ethernet cables. 2001

Chemistry for New Technologies

Meeting a rising need for piping and tubing to handle aggressive chemicals used in semiconductor production, higher-purity Teflon™ PFA HP grades resist corrosion and cracking. 2001

Extending Equipment Life

Changing the formula for lubricants in bearings, seals, and other industrial components with Krytox™ XHT offers extended machine life, improved safety, and high-temperature stability up to 400 °C (752 °F). 1999

Nonstick Cooking in China

Growing demand for cookware with Teflon™ nonstick coatings leads to the opening of a new facility in Shenzhen, China. The plant provides a regional nonstick coating supply for pots, pans, and woks made in Asia for both the domestic and export markets. 1998

Running Quieter

Patented soluble additives in Krytox™ lubricants enable bearings lubricated with oil to run more quietly and wear less, in uses ranging from generators to jet engines. 1992

Water-Repellent Clothing

The versatile properties of the Teflon™ brand find a new application, providing water repellency in windbreakers, rain pants, and other outdoor garments. 1988

Teflon™ Turns 50

The Plunkett awards begin, celebrating the world’s first fluoropolymer and Dr. Roy J. Plunkett, the man who discovered it. The awards honor the most innovative new fluoropolymer applications. 1986

The Statue of Liberty

As part of a major renovation, Teflon™ coating is used for a new inner stainless steel framework to protect against corrosion on the statue’s outer copper skin. 1985

Better Lubrication

Previously limited to specialized aerospace uses, the high-temperature tolerance, longer life, and temperature stability of Krytox™ lubricants become available for use in a broad range of industrial machinery. 1980

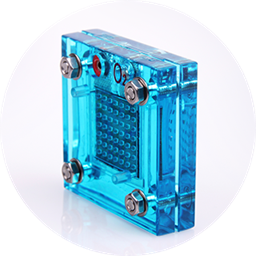

Fuel Cell Production

Nafion™—a conductive membrane originally used to control chemical exchange in chlorine production—finds new uses in the promising field of fuel cells for energy production. A dedicated manufacturing plant in Fayetteville, North Carolina, opens to help serve this growing field. 1970

Fire-Resistant Insulation

Ongoing materials research leads to a new class of ETFE (ethylene tetrafluoroethylene) plastics. Branded as Tefzel™, they offer lower flammability for improved fire safety in wire and cable insulation. 1965

Exploring Space

The challenge of space exploration creates a market for higher-performance products and leads to the first commercial sales of Krytox™ nonflammable lubricants for the Apollo space program. 1962

Early Fuel Cells

A promising new application for Nafion™ ionic exchange membranes is found in fuel cells. The NASA space program is an early adopter, using Nafion™ in fuel cells for the manned Gemini satellite program. 1960

Nonstick Cooking

The first frying pan using Teflon™ nonstick coating for cooking without oil, butter, or fat comes to market. It’s a hit in kitchens across the US, and a new category of cookware is born. 1960

Nafion™ Ionomer

Dr. Walther Grot discovers a material that is solid and chemically inert like Teflon™ fluoropolymer but also conducts electricity. Branded as Nafion™ membrane, the new material is initially used for safer chlorine production. 1958

Krytox™: Space Age Lubricants

As space exploration begins, engines and instruments need lubricants capable of working in extremes of both heat and cold. A range of new fluoropolymers, Krytox™ lubricants, answers the challenge, with the first uses in rocket gearbox lubricants and gyroscope oil. 1957

Viton™: First Fluoroelastomer

Failure is not an option for seals and gaskets in the process of engineering a new generation of faster, higher-flying US Air Force jets. Combining the flexibility of elastomers with the chemical and thermal resistance of fluorochemistry leads to Viton™—the first fluoroelastomer. 1951

Industrial Uses for Teflon™ Coatings

Initially used in a range of consumer products, the most slippery material in existence slides into industrial applications, such as cable insulation, where chemical and heat resistance add both durability and function. 1945

Trademarking Teflon™

The Teflon™ brand is trademarked for use in a new generation of consumer and industrial products. Applications multiply quickly, eventually including everything from nonstick cookware to stain-resistant clothing to cell phone antennae. 1942

The Manhattan Project

Although it was discovered in 1938, one of the first significant uses of polytetrafluoroethylene (PTFE)—soon to be branded as Teflon™—was to contain highly reactive uranium as part of the Manhattan Project that developed the first atomic weapons. 1938