According to the International Energy Agency and the U.S. Energy Information Administration, global energy consumption is expected to increase more than 28% by 2040.¹ However, energy production methods are critical to protecting our planet—and wasteful energy generation processes can contribute to climate change.

Nafion™ ion exchange membranes provide a clean solution to energy production, with water as the only byproduct. Fuel cells—another Nafion™ membrane application—convert hydrogen to electricity, which supplements intermittent power generated by renewables, a popular alternative to carbon-based energy sources. But relying on new energy generation sources is only part of the equation—excess energy storage and distribution will need to support the heavier loads society demands.

Chemours is exploring strategies to facilitate more efficient energy storage and management by supporting large-scale energy grids with flow batteries. These storage units utilize membrane technology, which helps grid systems match supply and demand effectively. Current and future smart cities and utility grids will also use the Internet of Things (IoT) to monitor energy use.

Addressing Climate Change with New Energy Sources

The world is focusing on clean energy as a way to ameliorate the effects of greenhouse gas emissions affecting the planet. Renewable energy sourced from using wind and solar sources or hydrogen production—while less environmentally harmful—carries other risks. Solar and wind-driven power generation is dependent on consistent availability, and hydrogen production remains inefficient and costly.

Engineers and designers specifically select Nafion™ membranes for fuel cells because of their thickness, conductivity, strength, and chemical durability. Nafion™ ion exchange membranes, dispersions, and resins play a vital role in three transformative clean energy industry areas that address these challenges: fuel cells, hydrogen production, and energy storage.

Fuel Cells

Fuel—or electrochemical—cells use an electrochemical reaction to convert chemical energy from a fuel (typically hydrogen and oxygen) into electricity. Engineers and designers specify using Nafion™ membranes because of their thickness, conductivity, strength, and chemical durability.

Hydrogen Production

Growing demands for clean energy has focused attention on hydrogen production. Innovators envision a society that uses hydrogen to fuel heating, power cars, and store and transport energy. While these hydrogen fuel cells provide a promising clean fuel target, current production methods rely on fossil fuels that generate greenhouse gas emissions, which contribute to climate change.

Hydrogen produced through water electrolysis offers a sustainable alternative. Using Nafion™ ion exchange membranes in electrochemical cells offers an environmentally safe way to generate large amounts of hydrogen without carbon dioxide emissions. Nafion™ membranes for water electrolyzers help:

- Reduce production disruptions

- Maintain consistently higher outputs

- Promote an environmentally sustainable solution to hydrogen production

Energy Storage

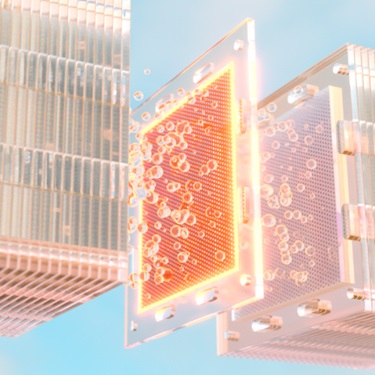

As populations, energy consumption rates, and available renewable energy increase, so will the need for reliable energy storage. Utilities store energy in flow batteries for distribution during peak demand, which stabilizes the energy flow of existing grids and balances the variable nature of renewables.

Flow batteries that use Nafion™ membranes offer safe, economical, and sustainable storage solutions. Nafion™ membranes’ durability and thickness can improve the performance of flow batteries used in large-scale energy storage. Because the electrochemical cells can work like fuel cells or rechargeable batteries, the Nafion™ membranes enable the cells to retain critical properties under continuous cycles of energy generation.

Clean Energy: Flowing Through the Future

Innovating energy production, storage, and distribution may influence the progress of other industries. Manufacturers will produce more electric and hydrogen-powered vehicles once those fuel sources become readily available and affordable. More smart cities will rely on grids and meters to automate efficient use. The power of chemistry will enhance these and many other applications within the energy industry, while working to reduce its environmental footprint.