Industrial Manufacturing

Fluoropolymers, the Backbone of Industrial Manufacturing

Today’s manufacturing and industrial applications demand highly specialized processes and stringent quality control. Industrial manufacturing infrastructure across industries and geographies is supported by high-performing fluoropolymers that can withstand thermally and chemically harsh environments.

Today’s manufacturing and industrial applications demand highly specialized processes and stringent quality control. Industrial manufacturing infrastructure across industries and geographies is supported by high-performing fluoropolymers that can withstand thermally and chemically harsh environments.

Without fluoropolymers, safety in industrial manufacturing doesn’t exist.

The unique combination of properties in fluoropolymers make them critical for a host of industrial applications and processing techniques. There are no alternatives that possess all of these unique properties while delivering the same high level of performance.

What are fluoropolymers?

What are fluoropolymers?

Fluoropolymers are a specialty plastic that possess a unique combination of properties that make them critical to modern life and a wide variety of sectors and industries. They are one specific class of per- and polyfluoroalkyl substances (PFAS), a group of thousands of chemical compounds with varying characteristics, properties, and environmental and safety profiles. Importantly, fluoropolymers do not pose a significant risk to human health or the environment when used for their intended purposes. Their unique combination of properties makes them fundamental to the products they enable.

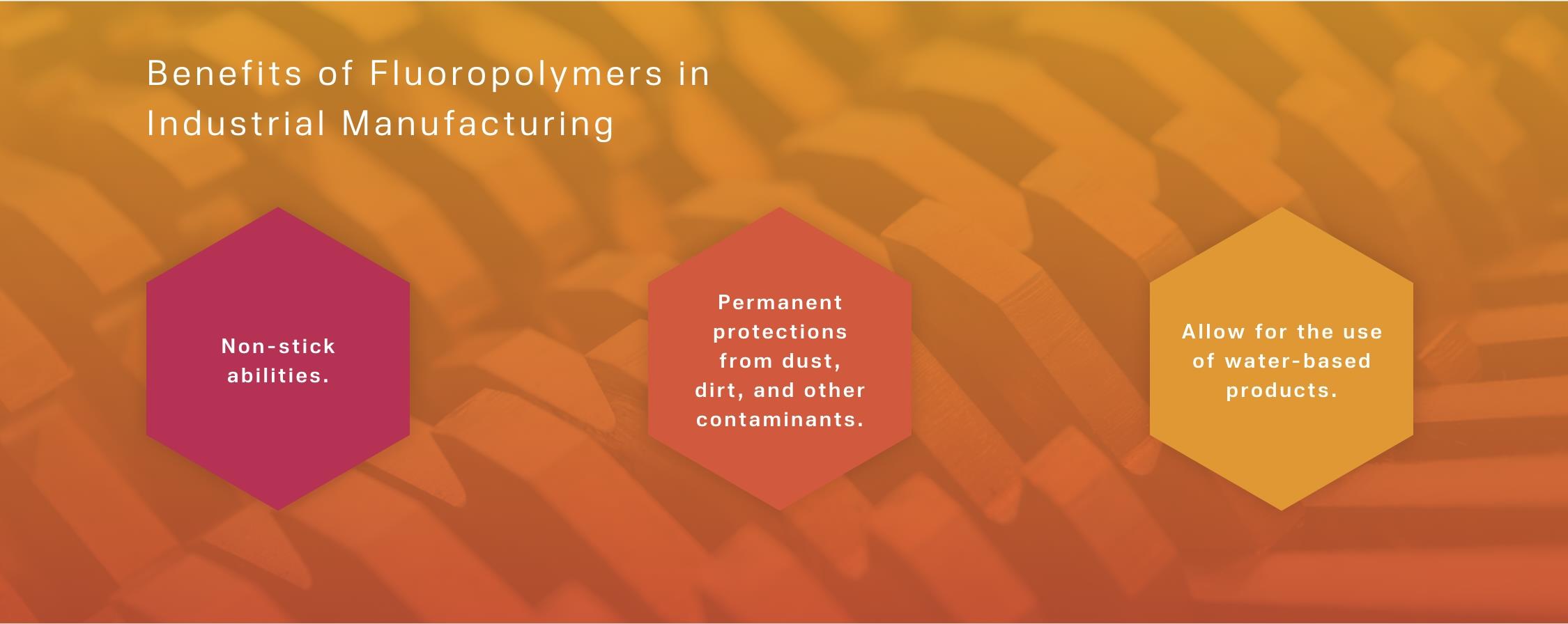

Critical Fluoropolymer Applications in the Industrial Manufacturing Industry:

-

Material on material effectiveness:

Fluoropolymers allow for easy movement and lubrication to reduce friction between products such as metal-on-metal, plastic-on-metal, and plastic-on-plastic.

-

Protection against contaminants:

Unlike hydrocarbons and silicones that go on wet and attract dirt, fluoropolymers create a seal, protecting products against external contaminants.

-

Water-based production:

Fluoropolymers are formed in a water-based solution, resulting in fewer contaminants from production forming and being released to the environment compared to alternatives.