Technological innovations today drive the realization of a cleaner, safer, and more efficient world tomorrow. In partnership with customers and communities, Chemours is applying advanced chemistry to provide transformative solutions that enable the next generation of goods and services that are vital to everyday life. Our cell phones, the Internet of Things, advanced electronics and smart devices, and even semiconductors. The 5G revolution is enabled by Chemours chemistry—the communications backbone of connected, advanced electronics today, and the essential ingredient in making the next great communications leaps possible in the evolving technology landscape.

Addressing Technology Challenges

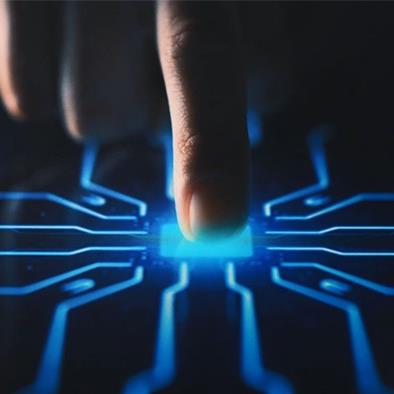

The Future of Connectivity

Better connections are making a better world—and chemistry is vital in creating it. The unique electrical, mechanical, and thermal properties of Teflon™ fluoropolymers help fashion error-free electronics purpose-built for the 5G era. 5G cellular networks are set to remake the digital world, and they’ll depend on a new generation of flexible and rigid circuit boards and the high-speed connections and cables—all made possible by Teflon™—that tie them together.

All the networks—cellular and wired—need an ever-growing number of high-speed data centers to keep the information flowing and enable people to make the most of high connection speeds. Cabling systems for local area networks (LANs) and other telecommunications applications also depend on Teflon™ fluoropolymers’ high-quality insulation properties.

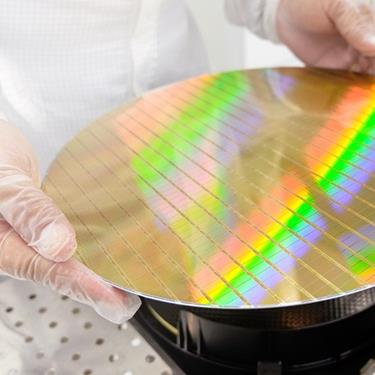

A Critical Link in Modern Electronics

“Microchips,” or semiconductors, are at the heart of most technology today. These brains of modern electronics are found not only in consumer appliances and electronics, but also in military aircraft and defense systems, electric grids, and cutting-edge healthcare equipment. Keeping semiconductors clean during the manufacturing process is essential for mitigating potential contamination. Teflon™ fluoropolymers’ unique characteristics protect microchips from damage by providing superior chemical resistance to corrosive damage during chip manufacture. These fluoropolymers enable manufacturers to maximize chip yields, minimize downtime, improve processes, and maintain micro-design consistency. Said differently, the brain behind the electronics that we use in our homes, cars, and systems everywhere in between rely on Chemours chemistry.

Durability and Strength in Consumer Wearables

Wearable consumer electronic products rely on fluoroelastomers for durability, comfort, and aesthetics. The nonreactive Viton™ fluoroelastomers withstand contact with sweat, lotions, moisture, and heat, adding versatility and durability to materials used in consumer wearables. UV-resistant Viton™ fluoroelastomers provide superior color retention, so bright colors won’t fade with use.

Creating Consistent Value through Innovation

Using deep knowledge and technical capabilities, we help solve our customers’ toughest problems and enable the creation of products that meet market demands. Together, with our customers and partners, we will continue developing and evolving our chemistry to provide solutions for the diverse challenges of the advanced electronics and semiconductor industries and 5G connectivity.