It’s just a powder or pellet. Yet the Teflon™ fluoropolymers used in computer chip production help make digital equipment smaller, faster, and more powerful—and live music more robust.

From Chips to Enhanced Guitar Riffs

At the rock concert spectacles of today, an audio engineer can layer tracks right onto a live performance, making the show sound like the band’s studio album. And should the concert venue lack a certain grandeur, the technician can add ambiance and reverb to the audio, making the hall feel bigger. And for that lead singer who can’t quite find the right pitch? Live auto-tune keeps him on key—at least as far as the audience can tell.

All these live-music effects come courtesy of digital technology that is advancing at a fast pace. With such progress, live-sound engineers find themselves working with tools unimagined a generation ago.

“We have the ability now to make the sound almost perfect,” says Keith Morris, Live Sound Instructor at the Conservatory of Recording Arts and Sciences in Tempe, Arizona. “And digital technology’s making all that possible.”

Helping make that digital technology possible is chemistry—particularly chemicals like Teflon™ fluoropolymers.

Shrinking Equipment, Bigger Effects

Today’s live-sound engineers use equipment like digital mixing boards for effects and digital audio workstations for recording and playback. Digital, of course, means the equipment is driven by computer chips, which contain semiconductors. It’s in the making of the semiconductor where chemistry comes in.

Teflon™ fluoropolymers help chip manufacturers achieve higher yields by reducing contamination during manufacture. Since Teflon™ is chemically inert, it’s nonreactive with virtually all chemicals. From wafer cleaning and etching to lithography and packaging, Teflon™ fluoropolymers appear throughout the semiconductor fabrication infrastructure, offering high levels of purity and unsurpassed protection against ionic and metallic contamination.

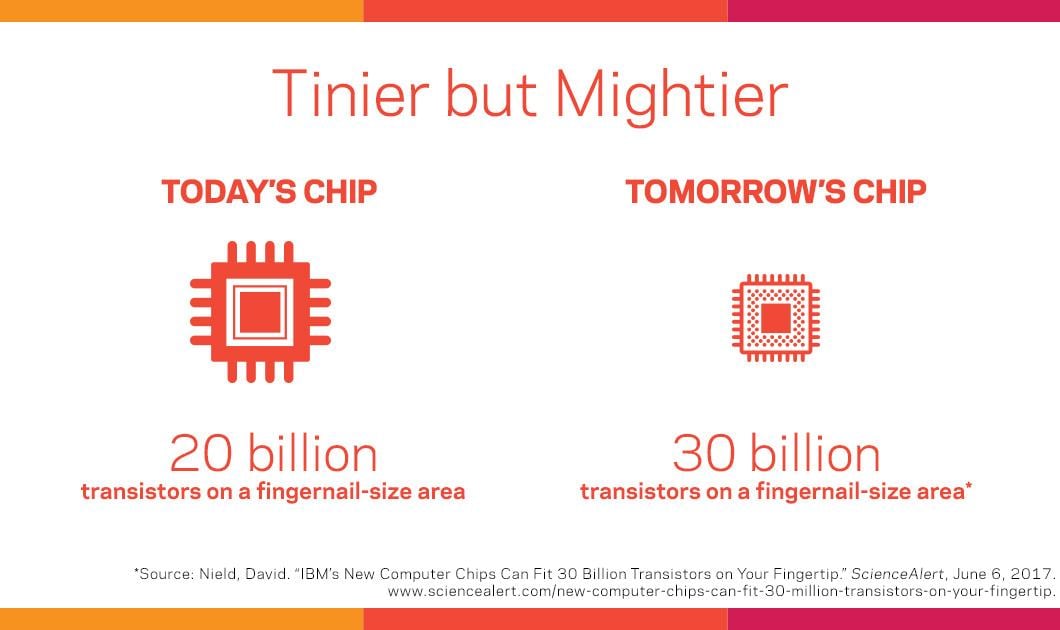

Ultimately, Teflon™ helps lead to higher-performing chips—essential as technology continues to evolve. One manufacturer recently announced plans to halve the size of its chip transistor gates from 10 to 5 nanometers, making it possible to fit 30 billion transistors on a chip the size of a fingernail1 (compared to a current state-of-the art chip that can fit 20 billion2).

“Evolving digital technology continues to make us reimagine what’s possible,” notes Katelyn Walck, Global Semicon Market Segment Leader. “And that extends to the live music experience. With our Teflon™ products, we’re helping to enable technologies that set the stage for the next generation of rock concerts and the electronics industry as a whole.”

Delivering Near-Perfect Sound

For concertgoers, the move to live digital sound translates to more bells and whistles in their music.

“Today, people are a lot pickier,” Morris says. “In the old days, not as much. You’d just go to a show and enjoy the show. Audiences now expect perfect sound.”

Live-audio engineers also benefit from digital technology. For one thing, an evolving chip-manufacturing process means shrinking gear.

“The largest revolution overall involves size, particularly with digital mixing consoles,” says Kyle Welch, Director of Live Sound at the Blackbird Academy, a professional audio school in Memphis, Tennessee. “A mixer that used to span six to eight feet now has a much smaller footprint—often with many more features than their analog counterparts.”

Behind such a console, “I can make any channel do anything I want,” Morris says. “And I can design a mix, save it in a digital file, and send that file to someone in Japan [for an upcoming concert]. When I get there, my show will be waiting at the console.”

Morris adds, “Remote control is a big deal too. I don’t have to be behind the console. I can call up the mixer on my iPhone. And that’s my dream—mix a show from home.”

And for the record, Teflon™ fluoropolymers are at work there too, helping build the semiconductors in the chips that turn smartphones into rock-concert remote controls and so much more.