At Chemours, we strive to make chemistry as responsible as it is essential. Our products play a critical role in our daily lives, the global economy, and a better future for our world.

This starts with being vital to modern living. From keeping food cold to improving reliability of medical equipment to enabling semiconductors in our smart devices, our fluoropolymer and fluorinated gas products are the best solution for hundreds of important applications in our daily lives. Our products also are necessary for the green economy. Nafion™ membranes are key to producing clean hydrogen, while Opteon™ low global warming potential solutions protect the food chain, enable heat pumps in electric vehicles, cool technology infrastructure, and drive energy efficiency. These are just some of the many ways that our products are supporting emerging sustainable technologies that enable decarbonization, electrification, and digital transformation.

For many of these critical applications, our chemistry represents the best solution and performance, delivering quality, reliability, safety and sustainability. While some chemical applications may enable one or two of these, many of our products possess a highly unique combination of properties to deliver unmatched levels of performance, making them the ideal choice for critical applications. These products are not only sustainable but also manufactured in a responsible manner that minimizes environmental impact. We’re making investments in the technology to reduce our own carbon footprint as we pursue a path to net-zero greenhouse gas emissions by 2050. At the same time, we’re also working to be good stewards of our natural resources through water stewardship, waste reduction and biodiversity enhancement.

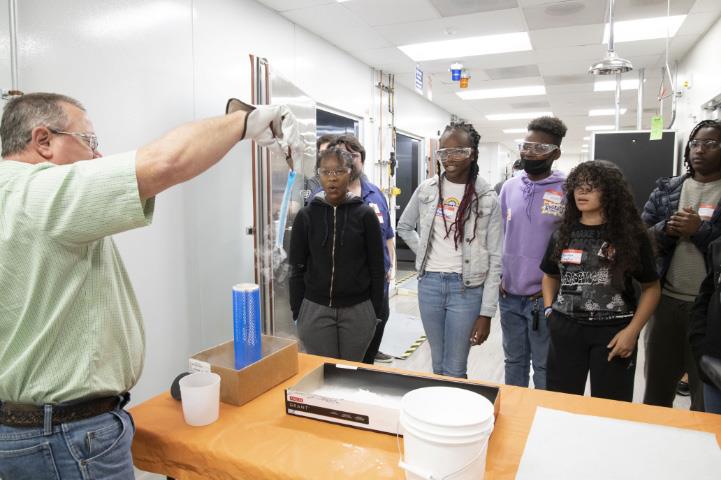

Driving all of these actions on behalf of our customers, our communities, our planet and each other are Chemours people. This team is dedicated, enthusiastic and among the most knowledgeable in our industry. They inspire us to not only be a great place to work but to be the greatest place to work in our industry.

In a constantly changing world that presents both new challenges as well as opportunities, we strive to meet the increasing demands and expectations of the global and local communities we serve—responsibly. Because, that’s essential.